UVLED Curing Equipment in Touch Screen Production

ouch screen is an inductive liquid crystal display device that can receive input signals such as contacts. When touching the graphic buttons on the screen, the tactile feedback system on the screen can drive various connecting devices according to the pre-programmed program, which can replace the mechanical button panel, and create vivid images through the liquid crystal display screen. Sound effect. In order to improve the efficiency, the solidification of touch screen has always been the most concerned issue in the industry.

The advantages of touch screen UV curing are as follows:

In the traditional LAMP mode, the heat dissipation surface of the high power light source is small, even with a large number of radiators, it can not quickly derive heat, so the light decay is fast. The heat dissipation surface of LED surface light source is tens of times larger than that of UV LED point light source, and the heat dissipation effect is very good. Life expectancy can reach 25,000-30,000 hours. The service life is not affected by the number of times of opening and closing. Compared with the traditional LAMP mode irradiator, the cable output has the advantages of frequent lamp replacement, high power consumption and ultraviolet fiber output. LED-UV can reduce the cost of equipment consumables and provide equipment utilization ratio for you.

The peak of LED is 365 nm, the spectrum is 360 nm to 370 nm, and there is no infrared light, so the surface of the irradiated product has no temperature rise, while the traditional LAMP ultraviolet irradiator will generally raise the surface of the irradiated product by 60-90 degrees, which will displace the positioning of the product and cause bad product.

Many LED light-emitting points are evenly distributed, and many of them are professional lens groups for optimum design of ultraviolet radiation. The uniformity of illumination is good. The variation of illumination intensity of edge and center is not more than 3%, which is incomparable with mercury lamp.

The output of light is stable, the illumination is stronger, the energy is higher, the uniformity is better, the instantaneous light is lit up, and the instantaneous power ultraviolet output is 100%. The irradiation intensity can reach 1200mW/cm2. The effective luminous efficiency is more than 10 times of that of mercury lamp, which improves the working efficiency.

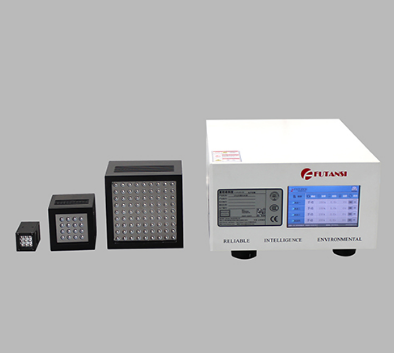

Futancy production: UV curing lamp, UV glue dryer, UV LED point light source, UV LED line light source, UV LED surface light source, UV LED oven, UV LED curing furnace, UV LED tunnel furnace

【Recommended reading】

- UV LED curing market will continue to grow

- UV-LED Light Curing Used in PCB Manufacturing Techn

- UVLED Curing Equipment for Electronic Coating

- Ultraviolet Curing Equipment for Mobile Phone Compo

- Sensor pasting for curing equipment

- Capacitance Jet Code UVLED Curing Machine

- UV LED Light Curing Contrast Thermosetting Machine

- What are the factors affecting the deep curing of U

- Why is UV LED curing machine popular

- What are the maintenance methods of UV LED curing e