The Latest Product Quality of UVLED Technology

Initially, the microcontroller had low power, limited heat and no hot problems, so its packaging was relatively simple. But in recent years, with the breakthrough of UVLED material technology

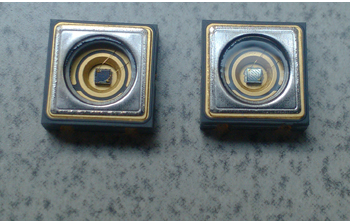

Advances in packaging technology will also change the early MCU shell package into a planar, large-scale multi-chip package module; currently from 20 mA to low

Power LED, developed to about 1/31 of the current high-power UVLED, a single leader input power of 1 W or more, or even 3 w, 5 W package more evolution.

Because the high brightness and high power UVLED system will be obtained from the thermal problems, the UVLED will affect the product quality advantages and the shortcomings of the LED components, so that it will quickly.

Heat release to the surrounding environment must begin with heat treatment at packaging level (L1 & L2). The industry's current practice is to use solder or hot paste to chip.

It is used with hot paste and then with radiators to reduce the thermal resistance of packaging modules. Many terminal applications, such as miniature projectors, automobiles and light sources, are in special use.

More lumens or thousands of lumens are needed for a given area, and the encapsulation of MCU is obviously not enough. For multi-chip LED encapsulation, the chip directly to the substrate is Future trends.

Heat dissipation is the main obstacle to the development of LED light source. Using ceramic or heat pipe is an effective way to prevent economic overheating, but heat management solutions

The purpose of increasing material cost and high power UVLED thermal management is to effectively reduce R junction-to-case material solutions through chips.

Low thermal resistance is provided, but high conductivity additions or hot metal methods provide heat directly from the chip to the outer package. However, LED cooling components and CPU cooling

But it is similar. It consists of heat sinks, heat pipes, fans and thermal interface materials. Of course, water cooling is one of the thermal Countermeasures of uvled. Currently the most popular

Large-size UV LED TV backlight module, 40-inch and 46-Inch LED backlight input power is 470W and 550W, 80% of which is converted into thermal energy, required.The heat consumption is about 360W and 440W.

Futangxi (Shanghai) Electronic Technology Co., Ltd. specializes in the production of UV LED point light source, UV LED line light source, UV LED surface light source, UV LED curing.UV LED light curing machine, UV LED glue curing machine, UV LED light source curing equipment.

【Recommended reading】

- What are the advantages of UVLED curing equipment?

- Ink Market

- Matching UV ink to UV light source

- How the cooling effect of uvled surface light sourc

- UV curing of the lens Why choose UVLED curing equip

- What are the methods of using uvled light curing ma

- What are the advantages of led curing equipment?

- What are the advantages of uvled curing equipment?