Where are UV LED curing machines used in LCD industry?

Where are UV LED curing machines used in LCD industry? Four Application Points

I. UV LED Exposure Technology

In the process of LCD production, the aim of photolithography is to coat the ITO conductive glass with photosensitive glue according to the requirement of product design, and to expose it to ultraviolet light, i.e. selective irradiation, so that the photoresist at the receiving part can react chemically and change the solubility of this part of the film in the developing solution. Then, the protective effect of photoresist is used to selectively etch the ITO conductive layer, and the pattern corresponding to the mask is obtained on ITO conductive glass.

Ultraviolet LED Modification (Ultraviolet Surface Modification)

At present, in the production process of liquid crystal display STN, it is mainly used in membrane treatment technology. It is very effective to improve the close connection between film and film, such as ITO film and photosensitive film, TOP coating and PI coating, etc.

3. Curing of LCD Sealing and Frame Glue by UV LED

The empty LCD cell without filling liquid crystal should be cured by ultraviolet ray of sealing glue, and the LCD cell with filling liquid crystal should be cured by UV LED irradiation of sealing glue.

IV. UV LED Cleaning

Photo-cleaning technology uses photosensitive oxidation of organic compounds to remove organic substances adhering to the surface of materials. After photocleaning, the surface of materials can achieve "atomic cleanliness".

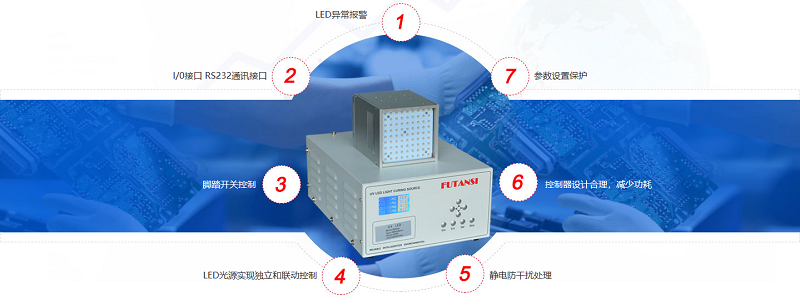

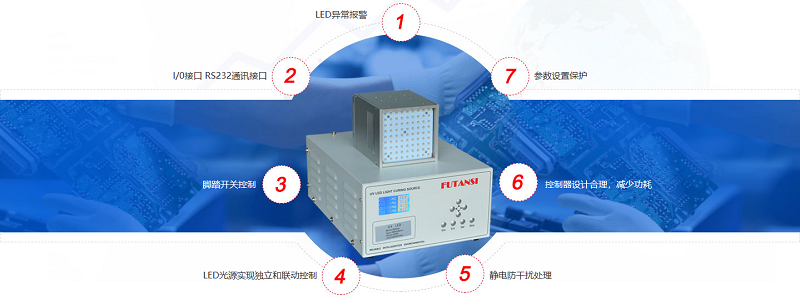

Futansi production: UVLED, UV LED light source, UV LED light source, UV LED curing machine, UV LED curing lamp, UV LED irradiator

【Recommended reading】

- Does the UV LED light source have a long service li

- Why is the power of the LED high when it's just tur

- Application Range of 365 nm UVled Curing Machine

- Several Applications of UV LED Cold Light Source on

- What are the types of LED light sources?

- What are the external and internal factors affectin

- These points must be noticed when using UVLED water

- Application of UVLED Curing Machine in Electronic O

- What are the applications of UV LED curing technolo

- What are the main application directions of UVLED c