Why is there always a layer of oil on the surface after UV d

Generally speaking, this is caused by oxygen blocking. Oxygen in the air is the enemy of most UV glues. On the surface of oxygen, UV adhesive seems to be difficult to cure completely. There are several ways to weaken or remove the influence of oxygen.

1. Faster curing has been achieved by using more intensive UV equipment.

2. Use Shorter Wave UV Lamp

3. Use inert gases (nitrogen and argon) to remove oxygen from the air

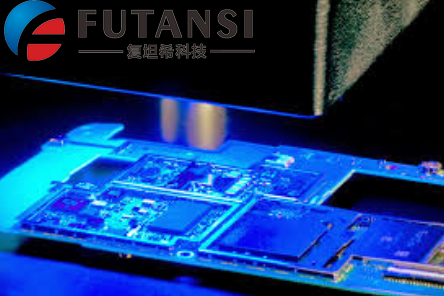

Ultraviolet LED series equipment produced by Futansi (Shanghai) Electronic Technology Co., Ltd: UVSP UVLN UVSF products, using ultraviolet curing technology to cure ink, coatings, adhesives and other ultraviolet photosensitive materials by polymerization. It is a new generation of light source with low power consumption, environmental protection and safety.

UV LED is a new high-tech product with green and environmental protection. With the maturity and wide application of LED technology, it will soon replace the traditional electrode-type UV mercury lamp. Compared with the traditional UV mercury lamp, the UV LED does not contain mercury or produce ozone. Based on its physical characteristics, it overcomes many disadvantages and limitations of the traditional UV mercury lamp. In the start-up process, the peak intensity can be achieved instantaneously without preheating and waiting. Ultra-low energy consumption and long service life are the best alternatives to traditional UV mercury lamps.

Futansi UV LED curing equipment is widely used in microelectronics industry, optical communication field, medical equipment field, PCB industry, optical industry, printing industry, scientific research and institutes.