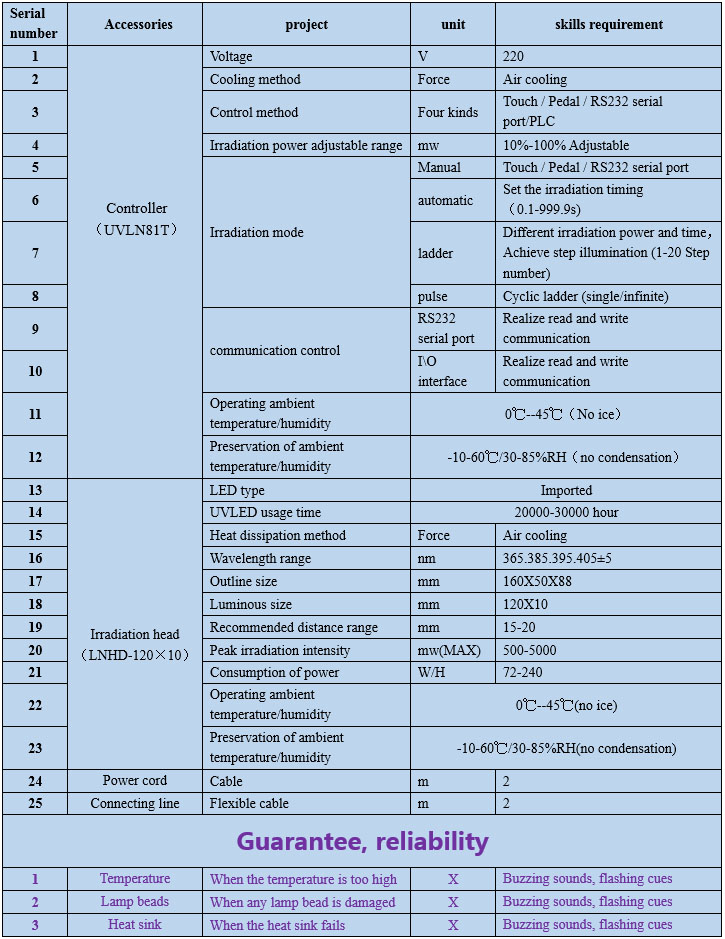

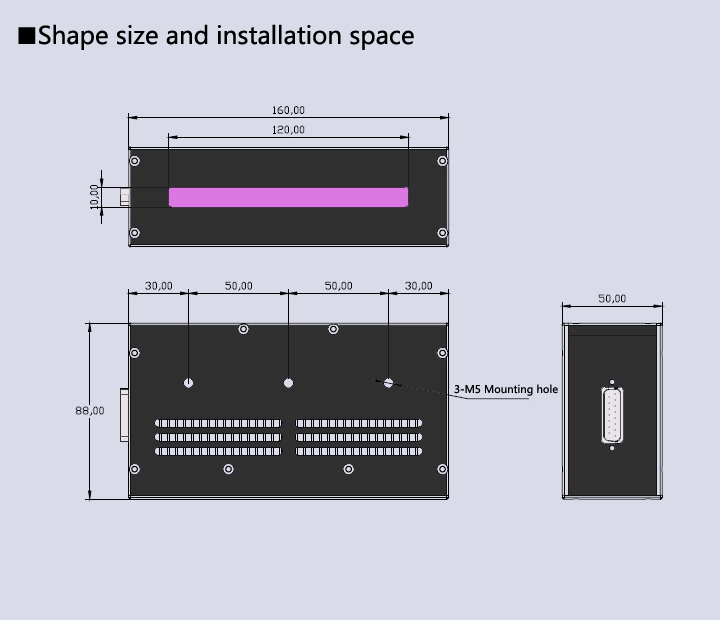

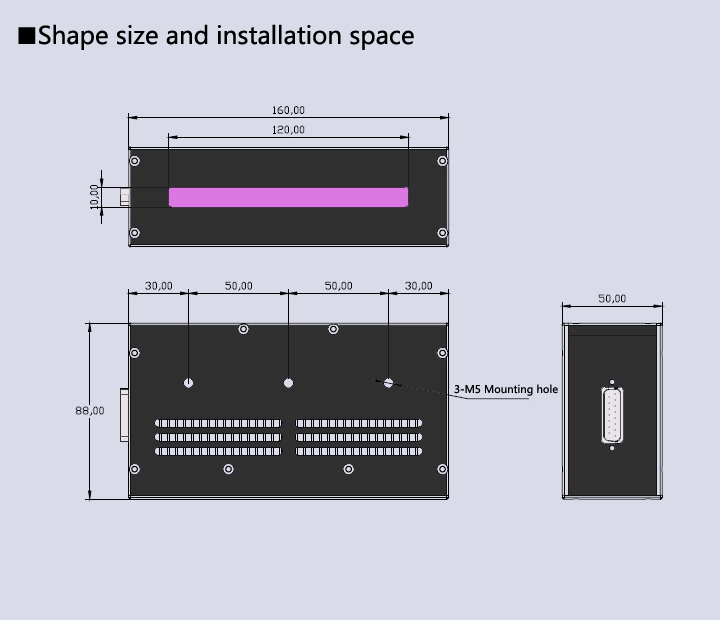

Product name:UVLED Line Curing Light Source-120×10

Product category:UVLED Line Light Source

Previous:UVLED Line Curing Light Source-150×10

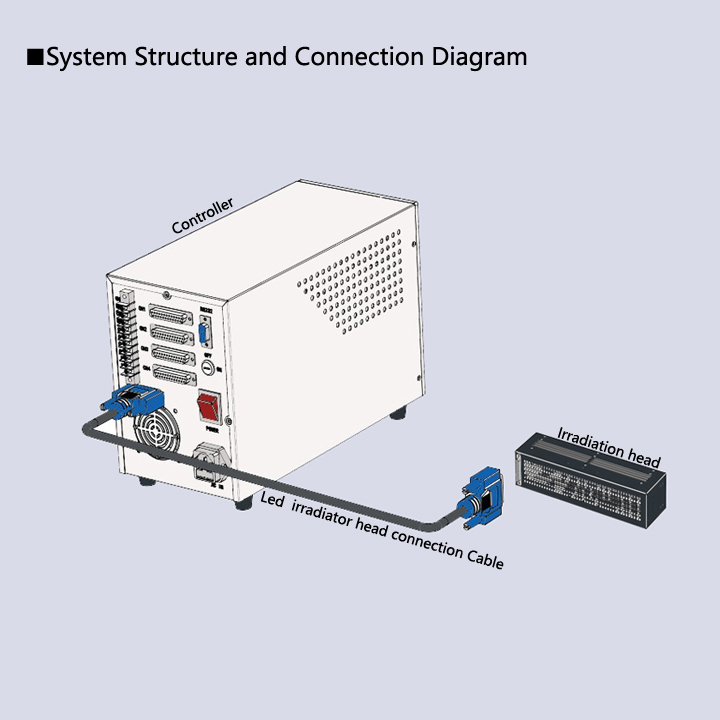

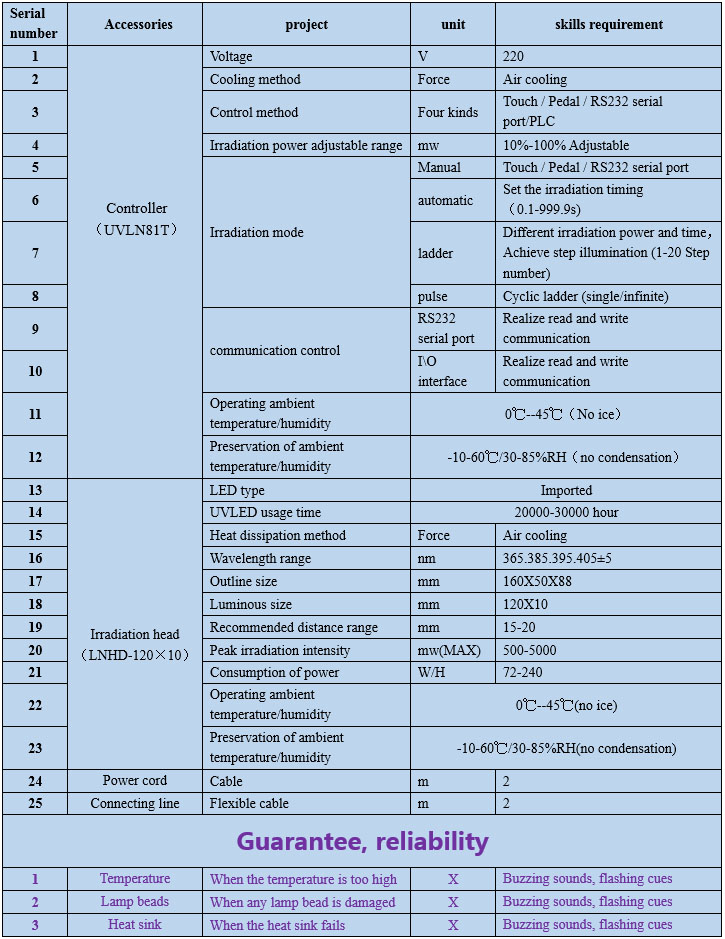

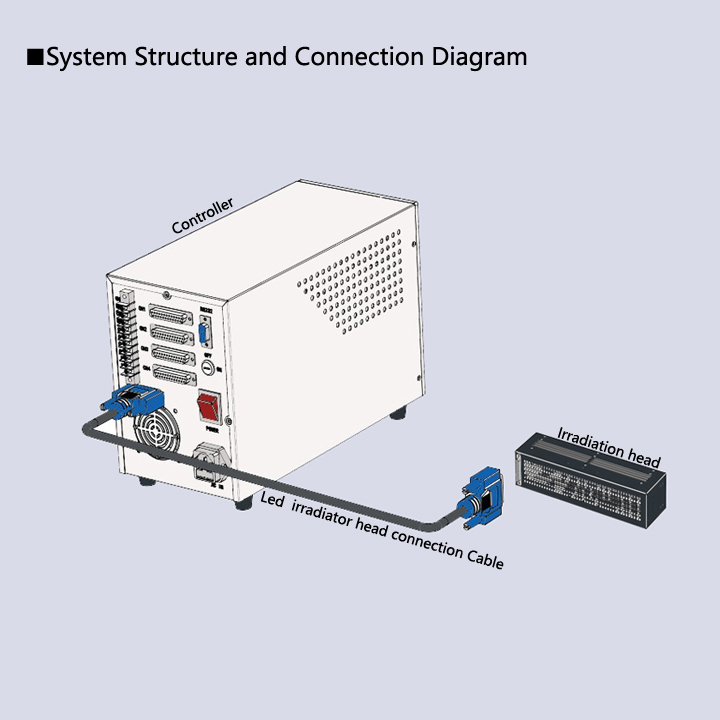

1. The UVLED light source is a cold light source, and there is no heat radiation, and the temperature of the

irradiated product is basically unchanged.

2. It does not need to be preheated to light up instantly, and instantly achieves 100% power UV output.

irradiated product is basically unchanged.

2. It does not need to be preheated to light up instantly, and instantly achieves 100% power UV output.

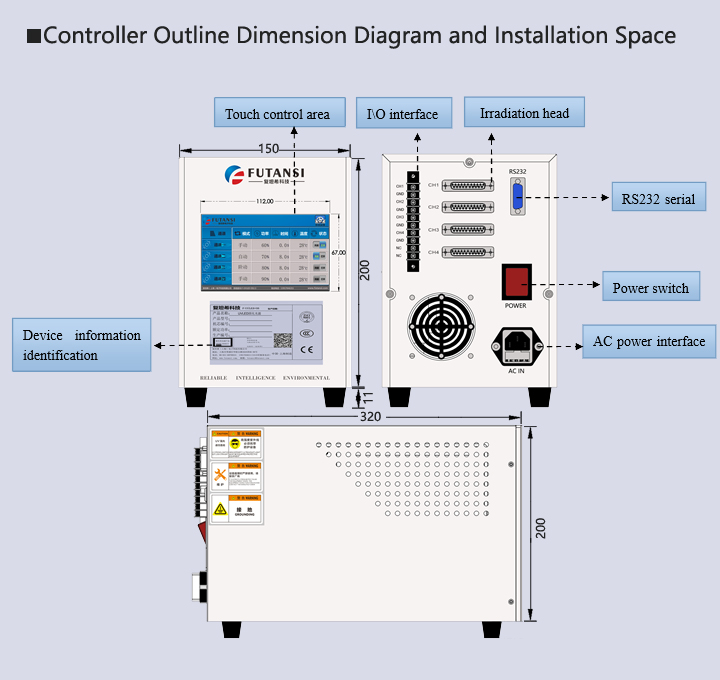

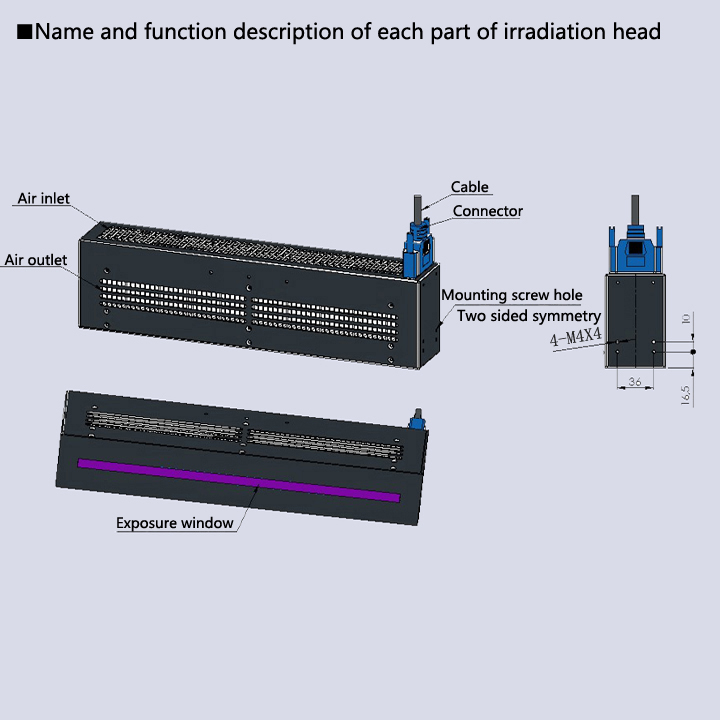

3. This machine adopts a small body, which is only 1/8 of the volume of the original high-pressure mercury

lamp irradiation machine. The illumination head is taken out from the back of the fuselage. Making the

device a breezeIntegration into fully automated production lines and equipment.

lamp irradiation machine. The illumination head is taken out from the back of the fuselage. Making the

device a breezeIntegration into fully automated production lines and equipment.

4. It does not use toxic substances, mercury, and does not produce ozone. It is a safe and environmentally

friendly alternative to traditional light sources.

5. Reduce cost, direct LED illumination, no need to output fiber optic cable, reducing cable loss.

6. LED mode has the characteristics of long life of light source. The life of LED chips reaches 20000-30000 hours.

7. Unlike the usual way of lighting the lamp, the LED can be UV-irradiated only when needed.

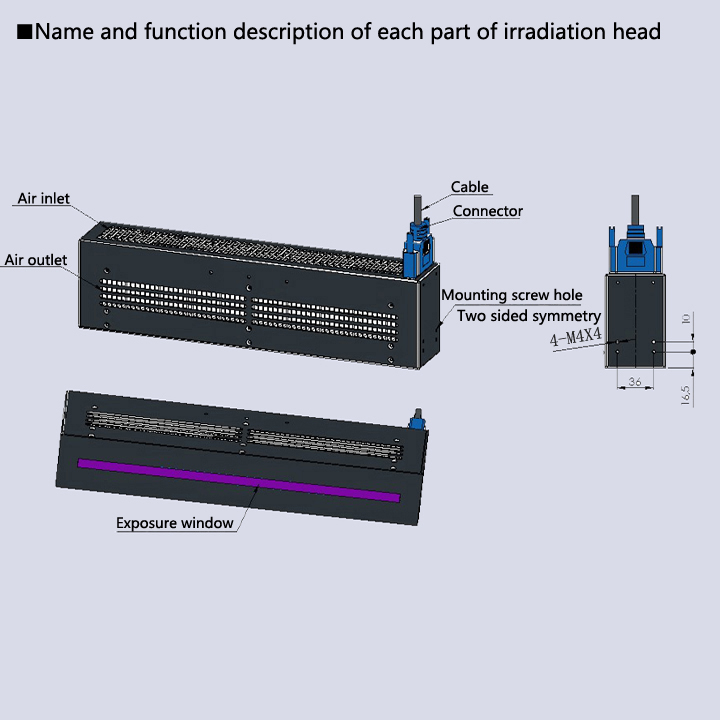

8. Independent control of multiple LED illumination heads can be applied to multiple independent stations

that require single-head output at the same time, effectively reducing equipment configuration. Multiple

LED illumination heads can also be used.

friendly alternative to traditional light sources.

5. Reduce cost, direct LED illumination, no need to output fiber optic cable, reducing cable loss.

6. LED mode has the characteristics of long life of light source. The life of LED chips reaches 20000-30000 hours.

7. Unlike the usual way of lighting the lamp, the LED can be UV-irradiated only when needed.

8. Independent control of multiple LED illumination heads can be applied to multiple independent stations

that require single-head output at the same time, effectively reducing equipment configuration. Multiple

LED illumination heads can also be used.

采购:UVLED Line Curing Light Source-120×10

Related products